We engineer to the max

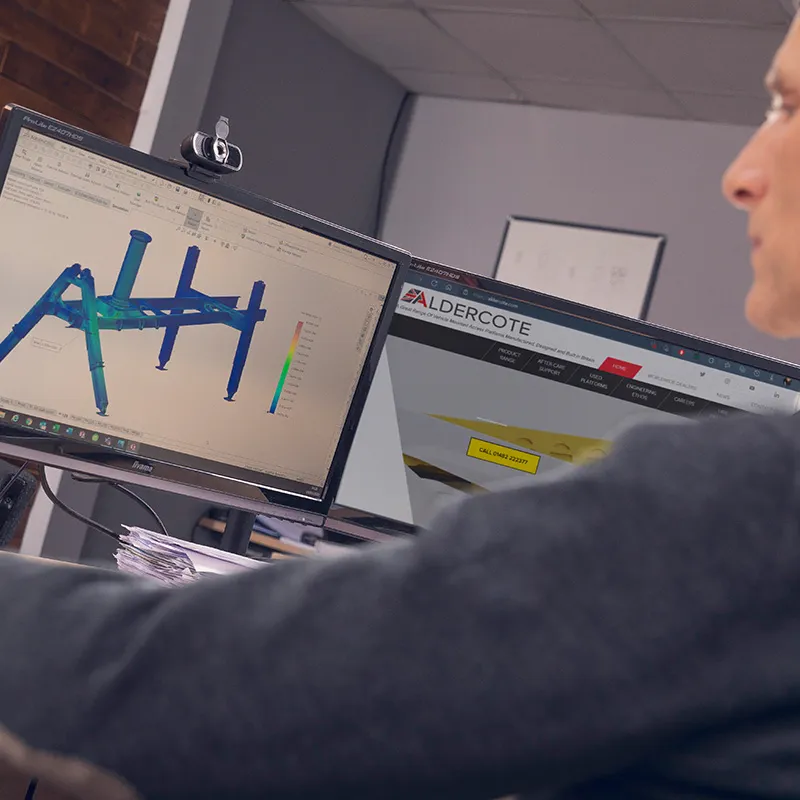

Working at height can be dangerous and the fact that operators are trusting us with their lives is central to our design ethos. All our platforms are tested to 150% overload and components are loaded to failure. New designs are subject to sophisticated numerical modelling, followed by finite element analysis (FEA), and This allows us to certify the safety and integrity of our platforms.

Efficient without compromise

Every component has been carefully designed and planned and has its function. We are constantly striving for the apex where innovation and safety meet by never over engineering our platforms.

After component design finalisation is completed we begin the process of weight minimisation. Our philosophy is every gram is worth saving. Each gram we save equals additional payload for your operator’s tools and equipment.

Minimising the manufacturing carbon footprint

We are a proud member of Made in Britain, since not only is all design, engineering and manufacture done in Hull in the East Riding of Yorkshire, but all components are also sourced in the UK.

Find out more about Made in Britain here.

E-Drive

E-Drive is our self-charging hybrid electric system which allows platforms to be operated without the vehicle engine running. This brings many operator benefits such as smoother, more accurate operation and faster platform speed. E-drive systems are quieter than traditional platforms (max. 55dB) and reduce exposure to exhaust fumes and deliver fuel and maintenance cost savings.

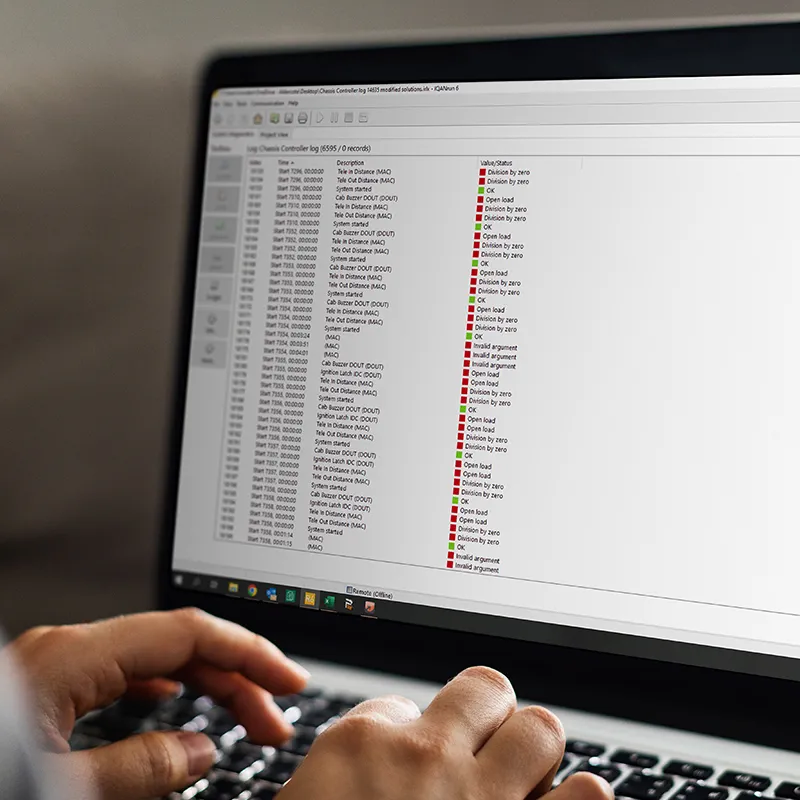

REMOTE DIAGNOSTICS SERVICE

Aldercote platforms are fitted with our remote diagnostic Bluetooth modem as standard. This tool allows us to remotely diagnose any problems and provide feedback to the operator, drastically reducing downtime and saving costly call-outs.

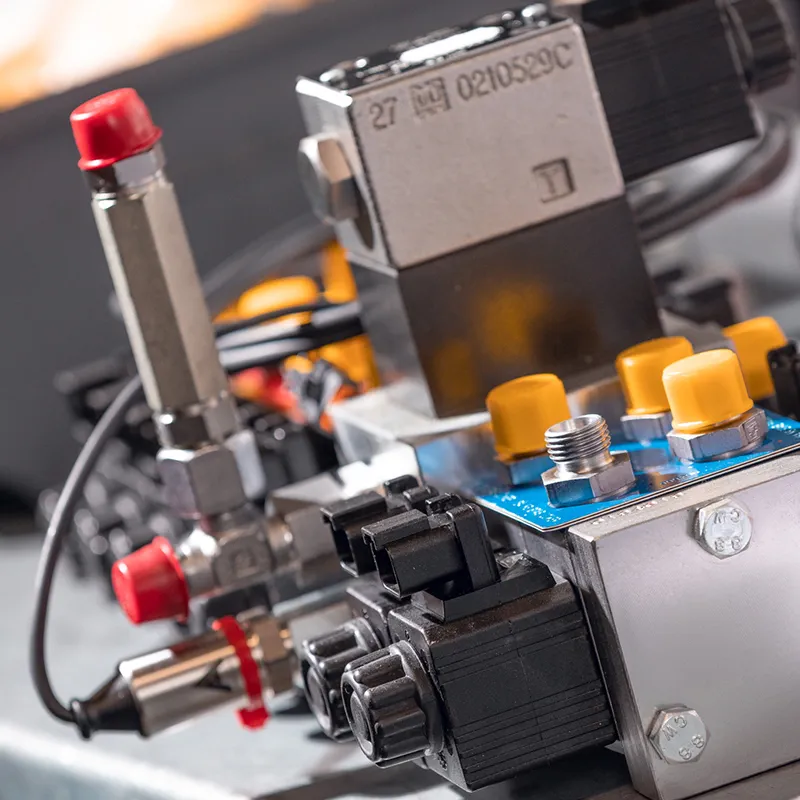

CONTROL SYSTEM

The control system is the brain of the platform and optimises its operation. Our control software, which we are continually developing is what delivers greater outreach and higher speed than competing platforms.

CREATIVITY

Our talented and dedicated design team includes expertise in software, electronics, mechanics, hydraulics, composite materials and mathematics. This combination of knowledge and experience breeds innovative solutions that are robust, elegant and efficient.

We meet the ISO 16368 standard for mobile elevating work platforms – this is the international equivalent of the BSEN 280, set by EU machinery directive. This means we comply with the following standards:

- EN ISO 4413 for hydraulic systems

- BSEN 60204 for electrical systems

- EN ISO 13849 for control systems.