VALUE: CUSTOMERS FIRST / OPERATOR FRIENDLY

Customer service is central to our ethos. We combine the experience and technical competence, with local knowledge. Whatever your problem, we will find a way to help you out.

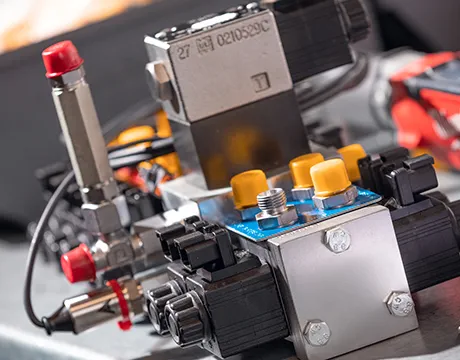

VALUE: ENGINEERING RIGOUR / INNOVATION / CREATIVITY

Evolving technology drives innovation. We continuously implement new processes, materials and control technologies to improve our products. We adopt new methods quickly and safely as they become relevant, and update designs rapidly in response.

VALUE: ALDERCOTE ‘FAMILY’ / ENJOYMENT @ WORK / TEAMWORK / PASSION / SINCERITY

Aldercote is a family-run business that puts people first. Our staff are passionate about their roles, be it in design, manufacture, sales or service. Our talented and highly experienced multi-disciplinary design team includes expertise in mathematics, software engineering, mechanics, electronics, composite materials and hydraulics.

VALUE: SUSTAINABILITY

We are highly conscious of trying to lessen the our impact on the environment, which is why we are the first vehicle mounted platform manufacturer to adopt electric drive as standard. E-Drive saves 1.5t CO2 emissions each year, and recharges in transit.

VALUE: RELIABILITY / DEPENDABILITY / EFFICIENCY

We know that operators place their lives in our hands. Our engineering team rigorously tests each product. Each platform is tested to 150% overload, and many components have been tested to destruction. We design our platforms to the max without over engineering and without compromise. Structural efficiency is one of our goals as each gram saved means you can carry more tools and equipment.

VALUE: INTEGRITY / TRUSTWORTHINESS

We are proud of our customer loyalty. Our platforms provide easy operation, exceptional uptime, and low maintenance. Other key features include exceptional working envelope and industry-leading payload. We are with your platform from cradle to grave, and when the vehicle needs replacement we can remount your platform required.

MILESTONES

-

Aldercote Founded

1999Founded in 1999 by Directors David and Paul Dillon, Aldercote was a specialist in vehicle engineering and the manufacture of aircraft de-icers and washers.

-

PA128 launched

2003Thanks to years of experience with other access platform companies, we were soon approached to design and manufacture a new reliable and robust van-mounted access platform for Hitachi Capital. The PA128 was launched.

-

Site Expansion

2004Site extended and a new workshop completed.

-

CAN bus system

2008First introduced CAN bus system into ‘the brain’ of our booms – this was pioneering engineering at the time. This development helped make the boom controls easy to operate.

-

Magglo Composites Purchased

2009Aldercote purchased GRP composite moulding company, Magglo Composites, and began manufacturing fibreglass products.

This year also saw the launch of the 16.5m van mounted platforms. -

Marc Paish joins the team

2013Marc Paish joined the board as Development Director and shareholder.

-

National Grid use system

2015We manufactured an insulated boom machine for National Grid.

-

Focus Business

2018We took the decision to concentrate on vehicle mounted access platform business.

-

E-Drive As Standard

2020We decided to make E-Drive – our self-charging hybrid electric battery system – as standard for all our vehicle mounted access platforms ...We don’t believe our environment should be an option!

Watch our video Aldercote E-Drive here. -

A busy year

2021In April, we purchased a new site so Aldercote and Magglo are on one premises on the edge of Kingston upon Hull, with easy access onto the main route into the city, close to the docks.

In May, we invested in, and took control of, our fabrication supplier Craven Fabrications, and moved the company into a new, larger premises in Newark, UK.

Call Now!

For further information or to arrange your demonstration